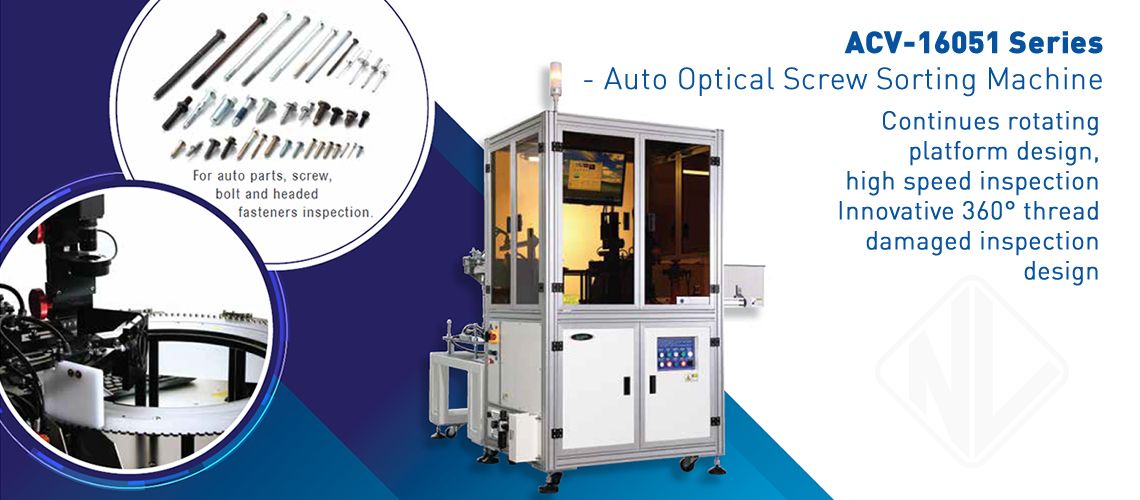

ACV-16051 screw inspection machine

03-10-2019

Nufast offers the most advanced High-Speed Inspection Technology capable of solving the toughest inspection and sorting problems for auto parts, screw, bolt and headed fasteners.

- For inspection small and medium diameter headed fasteners at a high rate of speed.

- Continuous rotating inspection design, with fast inspection speed and high precision

Features

- Application: Auto parts, screw, bolt

- Inspection Range: M3-M12, length 120mm

- Inspection Speed: 300~900 pcs/min depending on the actual feeding speed

- No. of CCD Camera : 1-6 cameras

- Professional inspection software: Graphic teaching mode, simple operation interface, easy to learn and use

- Options: Eddy current device / telecentric lens / 360-degree camera / automatic material supplementing system / paper box packing machine / OCR character recognition system

Inspection Criteria

fastener parts head width / height / pinhole depth / recess shape / burr in recess/ spiral thread / thread I.D. / thread E.D./ neck length / shank vertical / screw length / first thread / drunk thread / head crack / plating / insert nut thread / burr / dimension / etc

Specification

- Series No. ACV-16051

- Appling component Auto parts,larger fasteners

- Diameter of component M3~M12 standard

- Length of component 120mm

- Head Width 25mm

- No. of CCD 3 CCD

- Vision system Highly magnified CCD camera / light source sets

- Software Accuvision Pro-V II version 2.5

- Supply and output Feeding bowl / linear track / sorting bins (Good/NG)

- Speed 400~700 pcs/min

- Power AC 220 - 240V / 50Hz

- Mainframe Industrial computer, MITSUBISHI servo motor, Industrial CCD, Telecentric lens

- Machine spec. 1065mmL× 860mmW× 1,855mmH

Contact

Request technical data, quotation, enquire about a project please contact;

e: info@nufast.co.uk

t: +44 (0)1543 270 700

Related Links

Download pdf

Nufast Ltd can optically sort your free issue material

Or

Design and commission a bespoke machine for your components