Fast, Accurate Product Inspection

20-11-2020

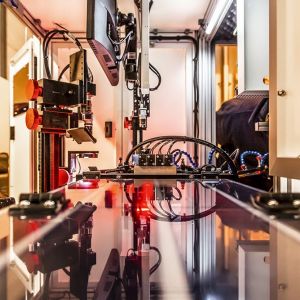

Nufast Optical Sorting is specialized in optical inspection and sorting systems for the automotive industry, with a focus on all kinds of machined products such as screws, nuts, rods, micro parts, general fastener, auto parts, precise semiconductor parts, threaded components.

In addition, Nufast’s optical inspection systems are also used for non-automotive applications, such as the optical inspection of medical related products, military components, electronic and other ODM parts.

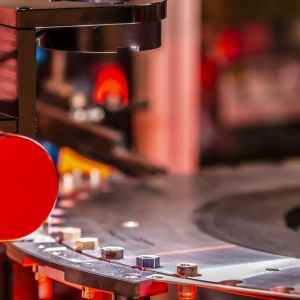

High Speed, High Accuracy, 100% Inspection Detects Variations;

- 360° Crack Optical Inspection

- 360° Thread Defect Optical Inspection

- Deformed - Broken

- Diameter - Roundness

- Burrs

- Swarf

- Concentricity

- Arc Radius

- Thread Presence

- Internal Thread Presence

- Material Mix Inspection

- Head Inspection

- Profile Dimensions

- Foreign Material

- Surface Finish

- Surface Defects

- Length, Width, Thickness

- Across Flats, Across Corners

We can help provide an innovative solution to your most demanding inspection requirements, if you have a product and are looking for a Comprehensive Inspection Solution- don’t hesitate to contact us…

We look forward to answering any questions you may have and the opportunity to discuss how our optical technology and sorting services can help achieve a reduction in PPM levels, a better ROI and ultimately increased sales

Contact Request

Technical data, quotation, enquire about a project please contact;

e: info@nufast.co.uk

t: +44 (0)1543 270 700