Streamline Production with Nufast’s Optical Sorting Services

26-11-2024

Boost Production Efficiency with Nufast's Optical Sorting Solutions

In high-performance production environments, downtime is the enemy. Faulty components slipping into the assembly process can cause costly delays, quality issues, and wasted resources. At Nufast, our Optical Sorting and Digital Inspection Services provide a quality-driven solution to safeguard your production line from these disruptions. T

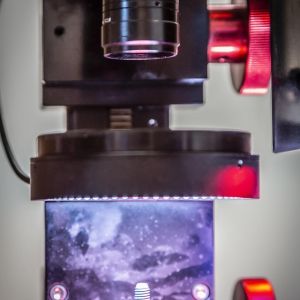

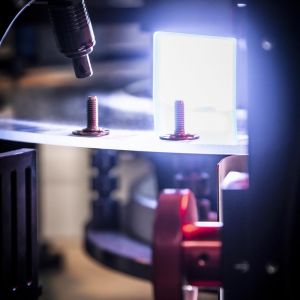

The Precision of Optical Sorting

Our optical sorting technology employs advanced imaging and algorithms to inspect components with exceptional accuracy. Each item is meticulously evaluated against precise specifications, ensuring only flawless components reach your production line.

Our process includes:

- 360° Crack Detection

- 360° Thread Defect Inspection

- Material Composition Analysis

- Dimensional Inspection (Length, Width, Thickness)

- Across Flats and Corners Measurements

- Head Geometry Inspection

- Profile and Dimensional Accuracy

- Foreign Material Detection

- Surface Finish and Defect Inspection

- Radial Damage Detection

- Metallurgical Integrity

- Burr and Swarf Identification

- Concentricity Measurement

- Arc Radius Inspection

- Thread Presence Verification

- Internal Thread Inspection

These comprehensive checks ensure that each component meets your exacting requirements, protecting the integrity of your production process.

Minimising Production Downtime

A single defective fastener or component can halt an entire production line. The ripple effects of such interruptions include lost productivity, increased costs, and potential delays in delivery schedules. By sorting components at our facility before they reach your site, we minimise the risk of these disruptions.

Key benefits for your production line include:

- Improved Workflow Continuity: Consistent quality prevents unexpected stoppages.

- Reduced Waste: Faulty parts are intercepted early, lowering material losses.

- Enhanced Productivity: Your team can focus on assembly and innovation rather than troubleshooting defects.

Tailored to Your Needs

We understand that every manufacturing process presents unique challenges. That’s why our Optical Sorting and Digital Inspection Services are fully customisable to suit your needs. Whether you require high-volume sorting, component analysis, rapid response our systems and logistics adapts to deliver precision results.

Partnering with Nufast

Entrusting your components to Nufast means partnering with a team committed to precision, quality, and reliability. Our advanced optical sorting solutions help you maintain stringent quality standards, enhance production efficiency and protect your reputation for excellence.

Pre-production quality control isn’t just preventative—it’s a strategic advantage. With Nufast’s Optical Sorting and Digital Inspection Services, you can streamline operations and keep your production line moving forward without interruption.

For more details about how our solutions can support your production line, contact us today.

Contact Us

Nufast Limited

8 Attwood Road

1 Burntwood Business Park

Staffordshire

WS7 3GJ

T: +44 (0)1543 270 700

E: info@nufast.co.uk