Optical Sorting Solutions Robust Quality Control

12-12-2024

Advanced Inspection Technology Serves a Range of Industries

Nufast Optical Sorting Solutions offer precise digital inspection and robust quality control, ensuring that every intricate component meets the highest standards. Our advanced technology serves a range of industries that rely on small parts for critical functions, safeguarding seamless production processes and uninterrupted assembly line operations.

Fasteners Manufacturers and Assembly Lines

For manufacturers and suppliers in the fasteners industry, optical sorting is a vital tool to prevent assembly line interruptions. By ensuring that every fastener meets precise specifications, these solutions minimise the risk of defects or incorrect parts disrupting production. This proactive quality control not only enhances efficiency but also helps increase customer satisfaction by delivering reliable components that meet stringent industry demands.

Nufast’s optical sorting technology enables manufacturers and assembly lines to:

- Detect and remove defective fasteners, preventing costly downtime and rework.

- Maintain consistent quality to meet client requirements and industry standards.

- Build trust with customers by supplying fault-free products that support seamless assembly.

Example Applications of Optical Sorting:

- Electronics: Guarantees flawless components for precision-dependent devices, preventing defects that could impact performance and production flow.

- Pharmaceuticals: Maintains the integrity of small parts used in medical devices, ensuring compliance with stringent industry regulations.

- Military & Defence: Delivers exceptional quality control for vital components, enhancing the reliability and safety of defence systems.

- Furniture Makers: Supports the production of detailed components, ensuring durability and functionality in designs while reducing returns and customer dissatisfaction in self-assembly furniture.

- Automotive: Provides crucial inspection of fasteners and small parts, ensuring safety, performance, and compliance with strict industry standards.

Nufast’s tailored optical sorting solutions help these industries achieve superior quality, streamline operations, and reduce costs, with precision at the heart of their continued success.

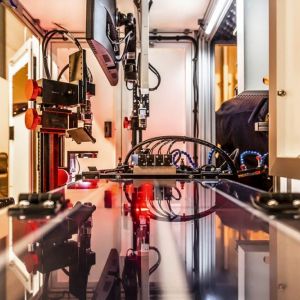

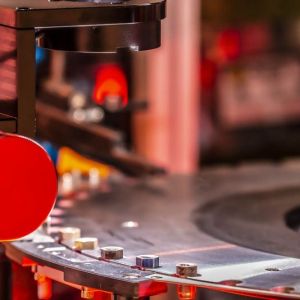

The Precision of Optical Sorting

Our optical sorting technology employs advanced imaging and algorithms to inspect components with exceptional accuracy. Each item is meticulously evaluated against precise specifications, ensuring only flawless components reach your production line.

Our process includes:

- 360° Crack Detection

- 360° Thread Defect Inspection

- Material Composition Analysis

- Dimensional Inspection (Length, Width, Thickness)

- Across Flats and Corners Measurements

- Head Geometry Inspection

- Profile and Dimensional Accuracy

- Foreign Material Detection

- Surface Finish and Defect Inspection

- Radial Damage Detection

- Metallurgical Integrity

- Burr and Swarf Identification

- Concentricity Measurement

- Arc Radius Inspection

- Thread Presence Verification

- Internal Thread Inspection

These comprehensive checks ensure that each component meets your exacting requirements, protecting the integrity of your production process.

Tailored Solutions for Every Challenge

Every manufacturing process comes with its own set of demands. That’s why Nufast’s Optical Sorting and Digital Inspection Services are designed to be fully adaptable. Whether you need high-volume sorting, detailed component analysis, or a rapid response, our systems and logistics align seamlessly with your specific requirements, delivering unparalleled precision.

Why Choose Nufast?

Partnering with Nufast means collaborating with experts dedicated to accuracy, quality, and dependability. Our state-of-the-art optical sorting technologies empower you to uphold rigorous quality standards, boost production efficiency, and safeguard your reputation for delivering exceptional results.

Pre-production quality control isn’t merely a preventative measure—it’s a strategic asset. With Nufast’s Optical Sorting and Digital Inspection Services, you can optimise your processes and ensure uninterrupted production workflows.

For more information on how we can support your manufacturing operations, get in touch with us today.

Contact Information

Nufast Limited 8 Attwood Road 1 Burntwood Business Park Staffordshire WS7 3GJ

T: +44 (0)1543 270 700 E: info@nufast.co.uk